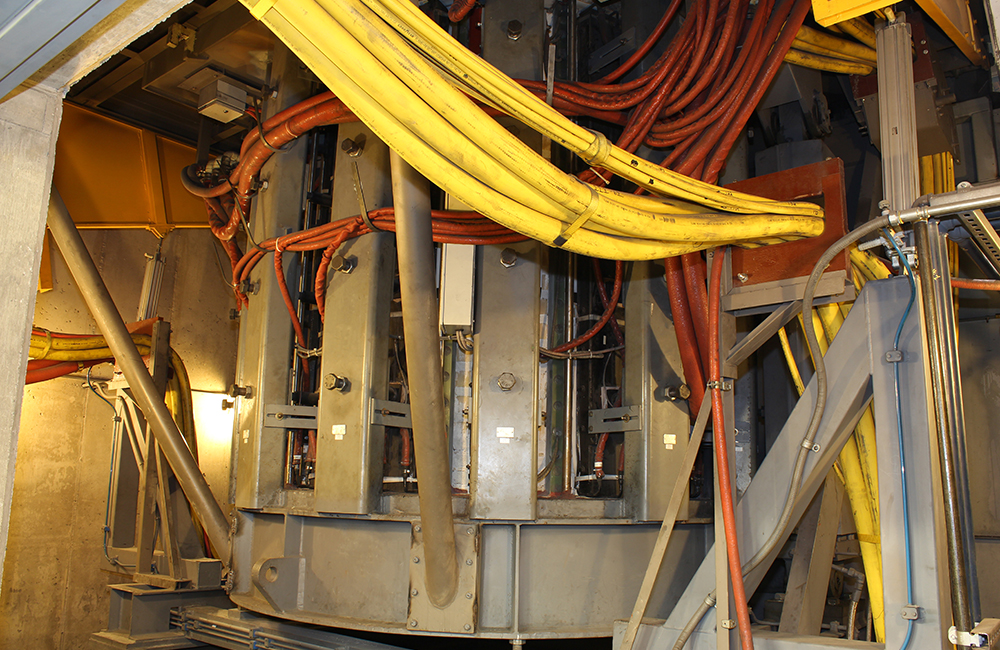

Steel Frame Furnaces

Steel Frame Furnaces combine the strength of a rugged steel frame with the easy accessibility of a frame furnace.

Due to our superior design and technological expertise, Inductotherm Steel Frame Furnaces are more efficient and easier to maintain than competitive furnaces. Steel Frame Furnaces feature rugged construction to minimize distortion during tilting and pouring operations. They are designed with a high freeboard and provide extra space for solid charge materials, enabling its cover (optional) to be easily closed as the charge melts, greatly reducing heat loss. The raised hearth (optional) provides a convenient fulcrum for easy slag and dross removal and also acts as a safety barrier for your workers, helping to shield them from excessive heat when the cover is off. The thick-walled tubing in Steel Frame Furnaces has a larger current-carrying cross section than comparably sized tubing so it offers lower resistance. This allows more energy to go into the melt. Every Steel Frame Furnace is designed for its structural strength with the help of specially developed computer-aided software.

Tech Specs

| Capacities | Standard Features | Optional Features | Factory Tested |

|---|---|---|---|

| 4 to 60 Metric Ton [4.5 to 66 Short Tons] | High Freeboard | Push-Out Lining System | Critical Components |

| Contact Inductotherm for Custom Solutions | Heavy Tubing | Load Cells | |

| Magnetic Shunts | Back-Tilting Systems |