Dura-Line ® Furnaces

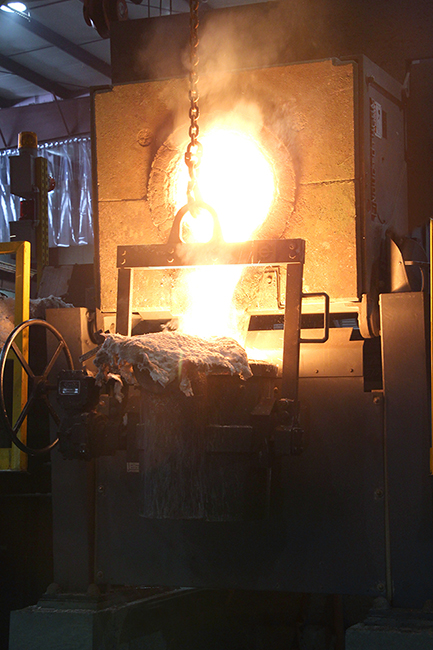

Dura-Line® induction melting furnaces are designed for rugged use and high-power density melting.

Dura-Line® induction melting furnaces are ideal for when you want big furnace features in a midsize induction furnace melter. These efficient and reliable induction melting furnaces offer high operational efficiency with a wide choice of capacities in a budget-friendly package.

Dura-Line® induction melting furnaces have a body constructed of heavy, cast refractory top and bottom sections with stainless steel reinforcement, providing a strong and rigid support for the heavy-duty, copper power coil and the working lining. The full-section cast metal side plates complete the structure and provide mounting support for the tilting trunnion and hydraulic tilting cylinders. Large diameter vertical and horizontal stainless steel tie rods ensure complete structural integrity.

The same construction is used for either hoist or hydraulic tilting furnaces, providing single-trunnion action and “nose-title” pouring. For front exiting leads, a metallic splash plate across the front of the furnace provides full protection to the coil during melting and pouring and is easily removed to connect the water-cooled leads and for maintenance. Hydraulically operated furnaces are provided with stanchions that protect the cylinders and hydraulic piping.

Advanced options for precise pouring

Dura-Line® induction melting furnaces with an optional double-trunnion, hydraulic tilt design offers the precision pouring control you need if your induction melting and casting operation requires a precise pour into a stationary opening. This design features two separate pivot axes for a smooth and controlled pouring action. As the double-trunnion, hydraulic tilt Dura-Line® induction melting furnace is tilted for pouring, the pivot point moves from the first axis, which is closer to the center of the furnace, to the second axis, which is in line with the tip of the pouring spout. This carefully designed tilting mechanism ensures minimum travel of the molten metal stream once pouring has started, while providing maximum “reach”. The double-trunnion, hydraulic tilt Dura-Line® furnace’s smooth and controlled pouring action makes it ideal when an exact pour position must be maintained. This action also permits faster controlled pouring.

Tech Specs

| Capacities | Standard Features | Optional Features | Factory Tested |

|---|---|---|---|

| 25 Kilograms to 3 Metric Tons [50 Pounds to 3.5 Short Tons] | Standard Features Cast Aluminum Furnace Body with Steel Reinforcement | Manually Operated Furnace Cover | Critical Components |

| Contact Inductotherm for Custom Solutions | Hoist Tilting | Hydraulically Operated Furnace Cover | |

| “Free Breathing” Coil Design | Hydraulic Tilting | ||

| Push-Out Lining System | |||

| Fume Collectors and Hoods | |||

| Double Trunnion (Hoist and Hydraulic Tilt |