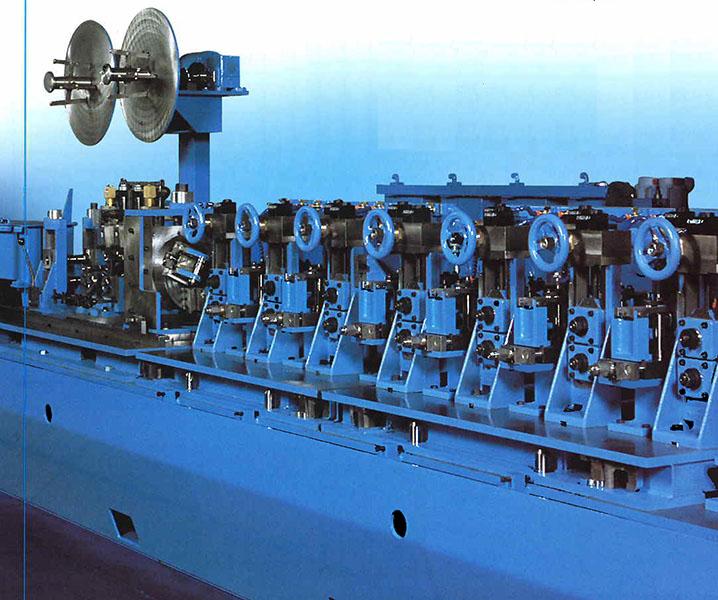

High Frequency (HF) Mill Systems

High Frequency (HF) Mill Systems — These are the work horses of the pipe and tube industry, and the hallmark of the T&H Lemont product line. When coupled with large hi-frequency welders and fast cutoffs, these hi-speed precision platforms, with up to 1000 feet per minute, serve the automotive, structural and mechanical tube markets on a year-after-year basis producing millions of feet as well as hundreds of thousands of tons of carbon steel, stainless steel or super hi-strength (100 KSI plus) pipe and tube. Our specialty is the abnormal and difficult, as in Diameter-to-thickness (D/t) ratios of plus 80 D/t and under 5 D/t.

Our Dual Capacity Mill is a pioneering concept in mill construction, with the WU-20/WU-40, combining two mill systems into one high speed production line. With minimal downtime, exact precision, and the ability to produce .5 to 6.625 inch (12 to 168.3 mm) diameter tubing, our customers have reached record production runs. Ideal for many applications, these mills are preferred for the manufacturer of hydro-formed tubing, sprinkler pipe, conduit, mechanical and structural tubing, varied disciplines that many manufacturers seek for expanded capabilities and broader market appeal, and so their profits. It is this very focus on the products you wish to make, that drives our engineering and technological achievements, coupled with the vast resources of the Inductotherm group of mill equipment companies, that places T&H Lemont head and shoulders above other manufacturers.

Be it carbon or stainless steel — T&H Lemont is the source you can trust. From start to finish we are the only single source that can stand behind your entire mill project. And when T&H Lemont’s mills are coupled with the high frequency solid-state welders and Alpha™ cutoffs from Thermatool Corp., these hi-speed precision platforms deliver the performance benchmark for the industry to beat. These are the systems of choice for automotive hydroforming, electrical conduit, structural and mechanical tube manufacturing applications.

Year-after-year, often running up to 1000 feet per minute, T&H Lemont installations the world over, turn hundreds of thousands of tons of carbon, stainless and/or super hi-strength (100 KSI plus) steel into millions of feet of pipe and tubing of superior structural integrity and strength. And while we offer a broad range in mill sizes, we inventory only the most primary pieces of any platform, allowing us to customize your application from a menu of our proven building blocks for standardized subsystems. These one-of-a-kind configurations (low/high D/t ratios, high strength materials, hi-speed, special finish, etc) are designed and delivered with the same fast turn around and protective warranties that equal or surpass industry norms for most standard size systems.

You should expect more. Exceeding customer expectations was the evolutionary driver behind acquisitions that created T&H Lemont. This foundation, with the complement of our place in the Inductotherm Group of companies, has collectively pioneered many technologies that drive the tube and pipe industry. And we approach each project knowing that what we did on the last project is just history, and that what we’ll do for you tomorrow, will be a part of your future and our legacy.

Technical Specifications

| Item # | Mill Type | O.D. Capacity Range | Wall Size Capacity | Material Capacity | Shape Capacity |

|---|---|---|---|---|---|

| WU-11M | Induction | 0.250 – 1.000 in 6.1 – 25.4 mm | 0.020 – 0.065 in 0.5 – 1.6 mm | Ferrous | Round |

| WU-15 | Induction | 0.375 – 1.750 in 9.5 – 44.5 mm | 0.020 – 0.083 in 0.5 – 2.1 mm | Ferrous | Round and Shapes |

| WU-20 | Induction | 0.500 – 2.500 in 12.7 – 63.5 mm | 0.020 – 0.134 in 0.5 – 3.4 mm | Ferrous | Round and Shapes |

| WU-20H | Induction | 0.500 – 3.000 in 12.7 – 76.2 mm | 0.030 – 0.160 in 0.762 – 4 mm | Ferrous | Round and Shapes |

| WU-25 | Induction | 0.750 – 3.500 in 19 – 88.9 mm | 0.025 – 0.160 in 0.64 – 4 mm | Ferrous | Round and Shapes |

| WU-35 | Induction | 1.000 – 4.500 in 25.4 – 115 mm | 0.060 – 0.240 in 1.5 – 6 mm | Ferrous | Round and Shapes |

| WU-40 | Induction | 1.500 – 5.500 in 38.1 – 139.7 mm | 0.060 – 0.280 in 1.5 – 7.1 mm | Ferrous | Round and Shapes |

| WU-50 | Induction | 2.000 – 6.625 in 50.8 – 168.3 mm | 0.080 – 0.330 in 2.0 – 8.4 mm | Ferrous | Round and Shapes |

| WU-60 | Induction | 2.000 – 8.625 in 50.8 – 219 mm | 0.120 – 0.437 in 50.8 – 219.00 mm | Ferrous | Round and Shapes |