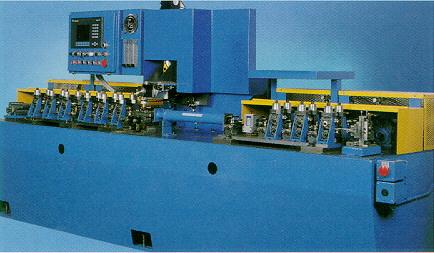

Laser & TIG Welded Tube & Pipe Mill Systems

Designed for the most precise fabrication of stainless steel and other precious metals such as copper, brass, platinum, titanium and even gold, T&H Lemont Laser and TIG mills provide the tightest tolerances for production. The mandate behind our unparalleled design is, in a word, control. Control over everything that can go wrong. With inline bright annealing systems and in-line weld operations; potential contamination of the seam is virtually eliminated.

A multi-cathode TIG welder provides simultaneous, constant and controlled arcs. Air driven jaw assemblies deliver near-zero distortion in end cuts, all managed and monitored with multi-section digital electronic controls. Our unique sequential welding configuration means increased mill throughput and performance by combining a power source with a high frequency arc that initiates the weld and shielding gas flow, all aimed at optimum consistency and integrity of the seam.

With all this rigid science at work, you still have the range and flexibility of varied production specifications such as four and six roll water cooled weldboxes with guide shoe capabilities all geared towards maximum versatility in product yield.

T&H Lemont understands the need for absolute control of your mill to ensure consistent and uncompromised quality of your product – the core upon which you stake your reputation and the same on which we build ours. No other mill system on the market delivers the weld integrity and tight tolerances of our Laser & TIG mills. And when you are working with expensive raw materials, yield and utilization is at an equal premium with output.

Combined with the uniform interfaces of our individual mill components and ancillary equipment, we are the only mill manufacturer to offer a complete system – providing you with a single source – and a single point of responsibility for every point of every process, from conception to installation and training.

Technical Specifications

| Item # | Mill Type | O.D. Capacity Range | Wall Size Capacity | Material Capacity | Shape Capacity |

|---|---|---|---|---|---|

| WU-8 | Laser, TIG | 0.090 – 0.035 in 2.3 – 9.5 mm | 0.006 – 0.035 in 0.15 – 9 mm | Nonferrous Alloys | Round |

| WU-11 | Laser, TIG | 0.150 – 0.750 in 3.8 – 19 mm | 0.010 – 0.050 in 0.25 – 1.3 mm | Nonferrous Alloys | Round |

| WU-1M | Laser, TIG | 0.250 – 1.000 in 6.4 – 25.4 mm | 0.020 – 0.065 in 0.5 – 1.6 mm | Nonferrous Alloys | Round |

| WU-15 | Laser, TIG, Multicathode | 0.500 – 2.500 in 12.7 – 63.5 mm | 0.020 – 0.134 in 0.5 – 3.4 mm | Nonferrous Alloys | Round and Shapes |

| WU-20H | Laser, TIG, Multicathode | 0.500 – 3.000 in 12.7 – 76.2 mm | 0.030 – 0.160 in 0.762 – 4 mm | Nonferrous Alloys | Round and Shapes |

| WU-25 | Laser, TIG, Plasma, Multicathode | 0.750 – 3.500 in 19 – 88.9 mm | 0.025 – 0.160 in 0.64 – 4 mm | Nonferrous Alloys | Round and Shapes |

| WU-35 | Laser, TIG, Plasma, Multicathode | 1.000 – 4.500 in 25.4 – 115 mm | 0.060 – 0.240 in 1.5 – 6 mm | Nonferrous Alloys | Round and Shapes |

| WU-40 | Laser, TIG, Plasma, Multicathode | 1.500 – 5.500 in 38.1 – 139.7 mm | 0.060 – 0.280 in 1.5 – 7.1 mm | Nonferrous Alloys | Round and Shapes |

| WU-50 | Laser, TIG, Plasma, Multicathode | 2.000 – 6.625 in 50.8 – 220 mm | 0.080 – 0.330 in 2.0 – 8.4 mm | Nonferrous Alloys | Round and Shapes |

| WU-60 | Laser, TIG, Plasma, Multicathode | 2.000 – 8.625 in 50.8 – 219 mm | 0.120 – 0.437 in 50.8 – 219.00 mm | Nonferrous Alloys | Round and Shapes |