Pipe Heating Clam Coils

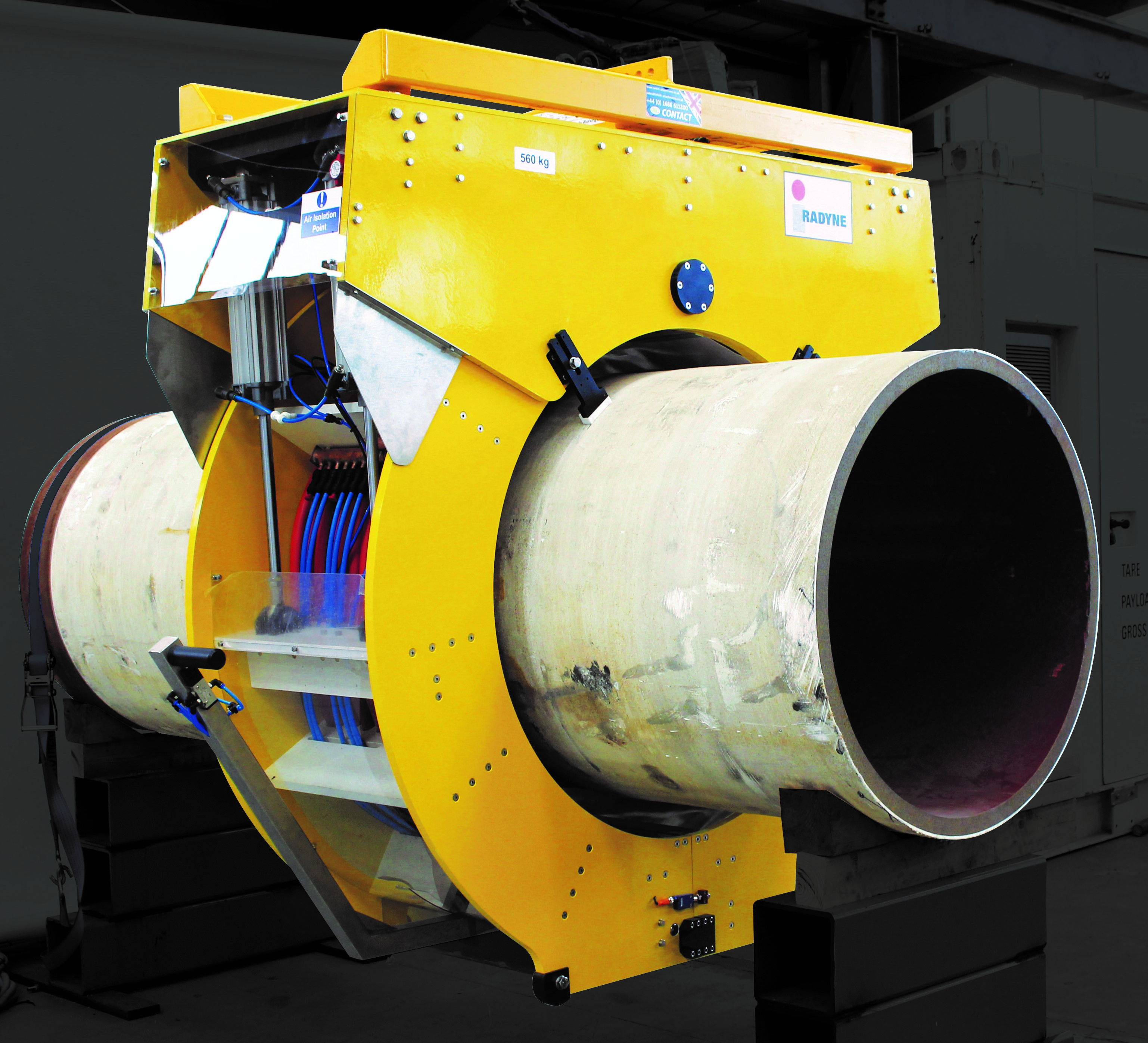

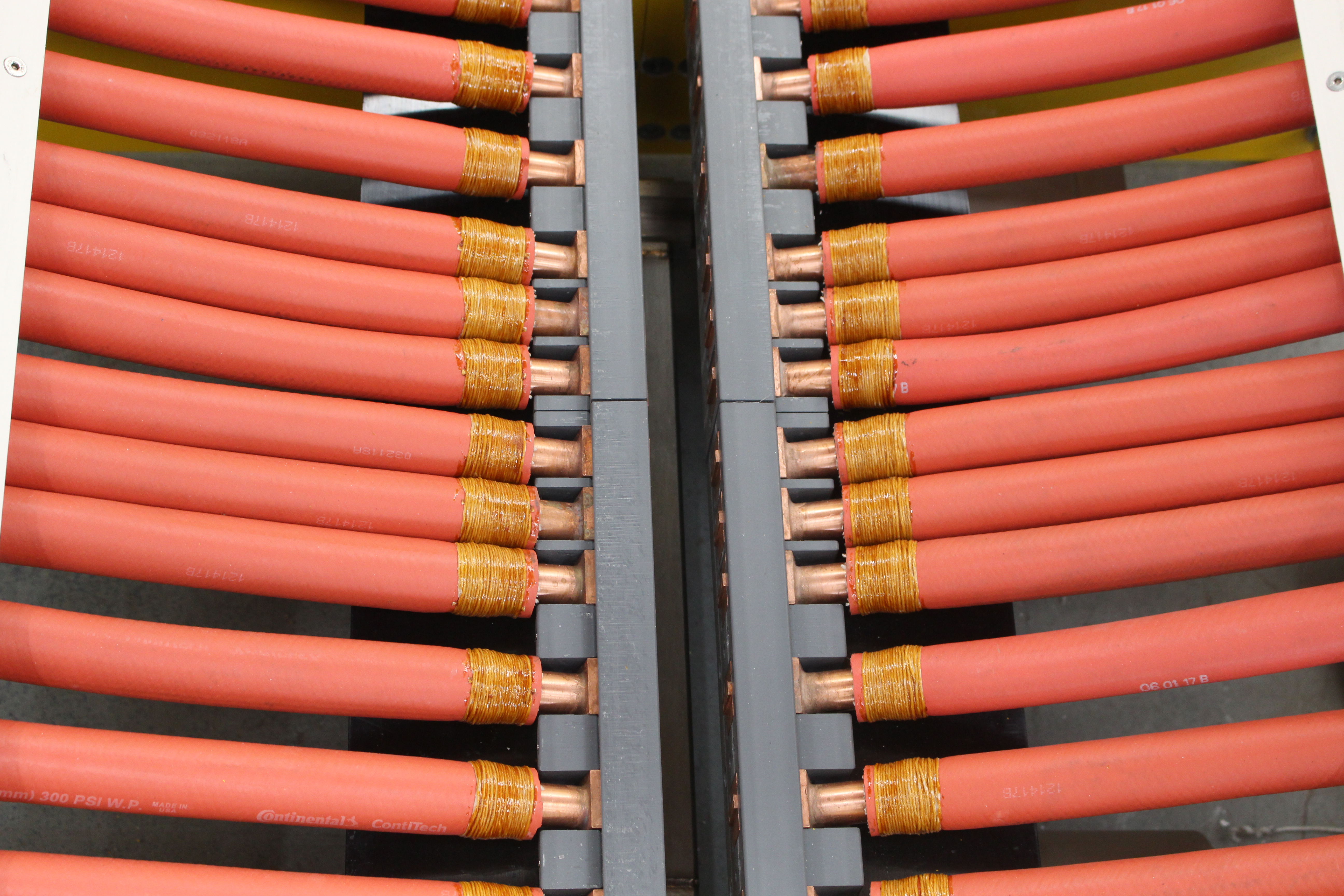

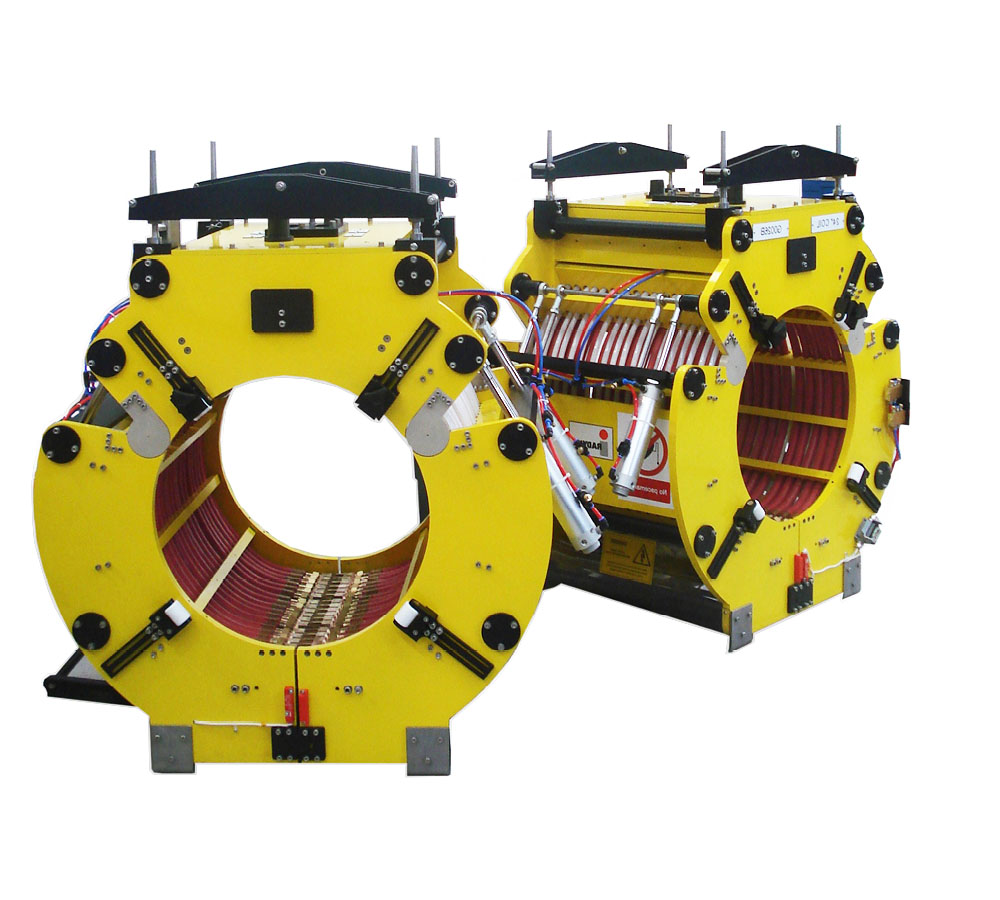

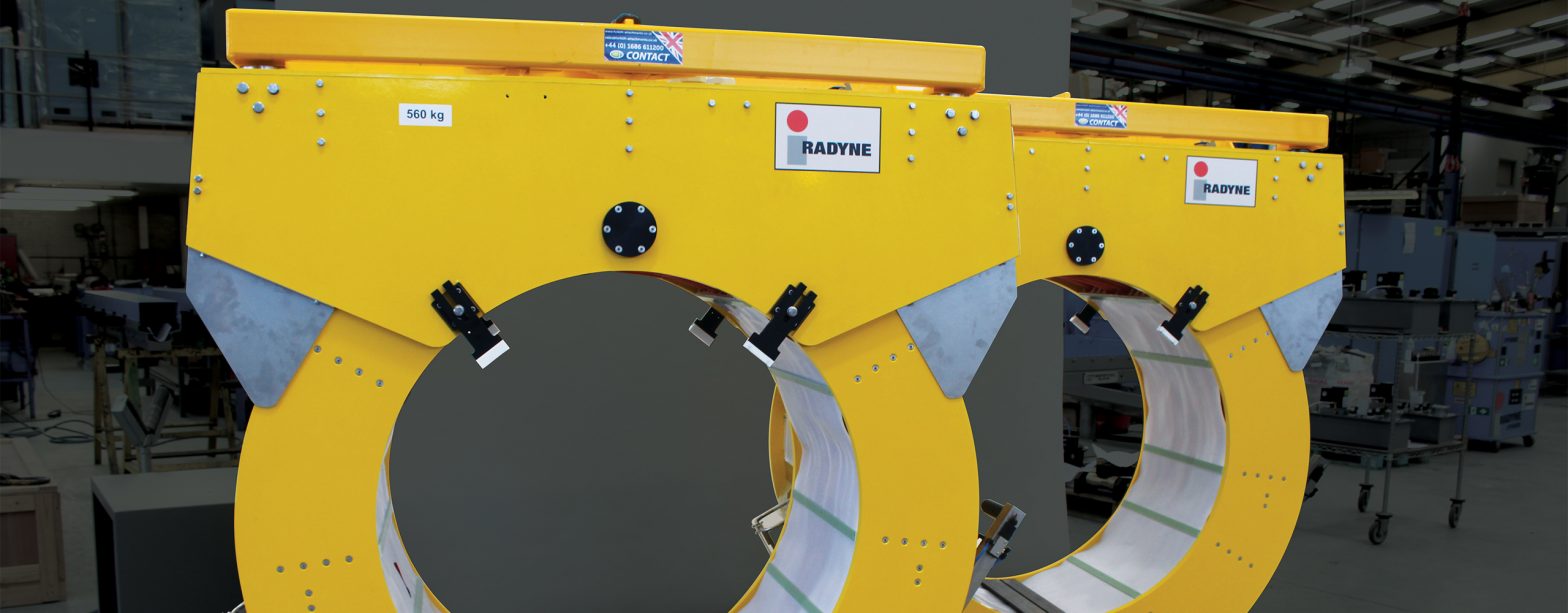

Radyne Pipe Heating Clam Coils provide induction heating of pipe line field joints for a range of applications. High powered water cooled induction coils with reliable quick action electrical contacts allow for rapid and efficient heating. The coil opening mechanism is pneumatically actuated for positioning on and off the pipe.

The Clam Coil frame is manufactured in a non-conductive composite material with switches ensures correct coil closure before application of power. Optional integrated pyrometer and PLC control system allow for an automated heat cycle and temperature monitoring.

Designed to suit your needs, our coil heat profiles are optimised using CAE software to give uniform heating in order to meet rigorous field joint specifications. The Heat Affected Zone is minimised to only the required area, reducing unwanted heating of the parent coating.

Radyne Clam Coils are typical designed for optimal operation with the Radyne 450 kW TC3 induction convertors and operated with basic local controls or as part of the advanced integrated Merlin control systems.

Applications

Heat Shrink Sleeve Application

Radyne Offshore Clam Coils are used to preheat the field joint prior to the application of heat shrink sleeves. The Radyne induction-powered Clam Coil system offers quicker, safer, controllable and repeatable heating compared to the use of gas fired torches.

Heating Prior to Welding

Pre-weld heating is fundamental to the process of butt welding, to ensure the integrity of the welded joint. The Radyne induction heat process provides the perfect method of heating pipes to the correct temperature within closed limits.

Post Welding Heat Treatment

For post weld heat treatment of field joints, PLC controlled heat programs power the Clam Coil to give the required temperature and heating time as dictated by the steel grade of the pipe.