Small Caliber Ammunition Annealing Systems

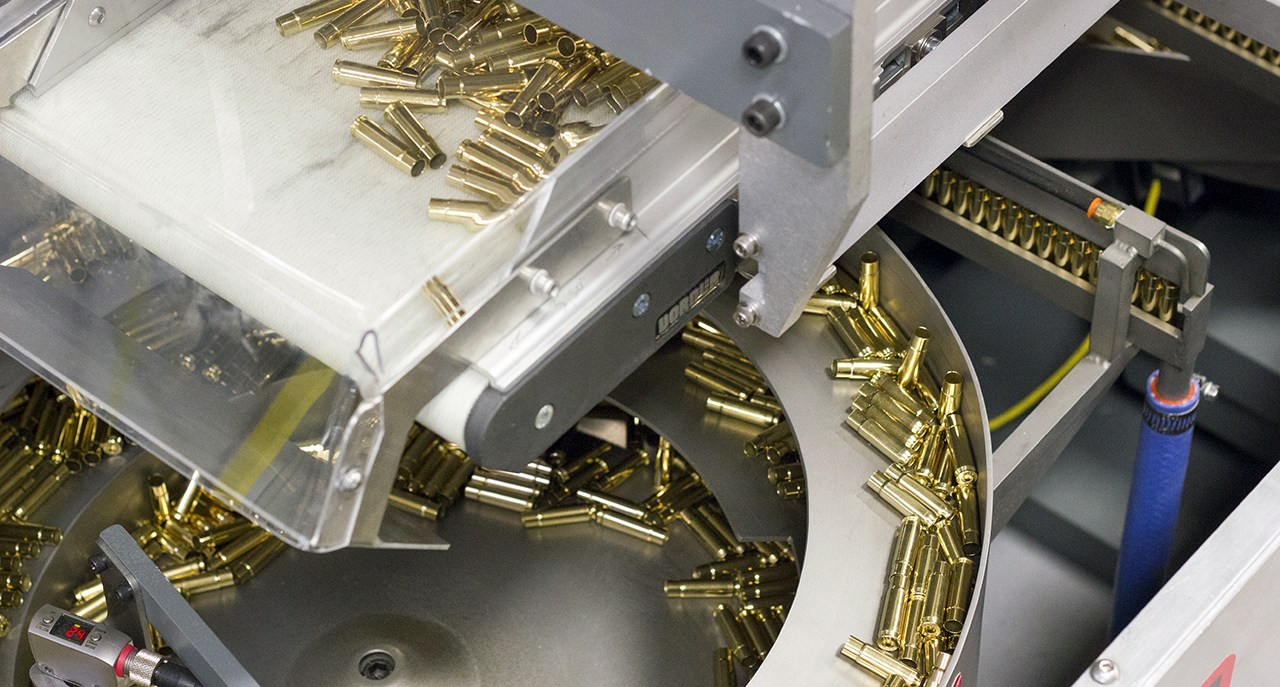

Radyne Small Caliber Ammunition Annealing Systems and Cartridge Annealing Systems use a continuously fed indexing system to anneal ammunition cartridges with extreme precision. Cartridge Annealing Systems with single or dual feed streams are available based on your production rate needs.

Radyne systems are capable of heat treating and forming quality ammunition, creating specialized fragmentation patterns, specific penetration characteristics, and precise annealing profiles.

*Licensed Federal Firearms Manufacturer

Small Caliber Ammunition Annealing Systems

Each model features a part loading mechanism, vibratory bowl feed system, cam-driven escapement, continuous feed dial indexer, and optional gas quench. Radyne systems support annealing of a variety of brass shell sizes with production rates ranging from 110 – 240 parts per minute.

|

|

Cartridge / Brass Induction Annealing Systems

Radyne provides a range of high throughput, industrial-grade automatic cartridge and jacket brass induction annealing systems that cover calibers from 0.223 to 0.68 at rates up to 320ppm.

New for 2018 – Improved feed mechanismRadyne’s new cartridge feeding system is able to individually separate cartridges from allowing processing of parts before “heading” without risk of jams or part damage. The Cartridge Annealing System is able to process round bottom parts and anneal closer to the bottom of the part based on our new innovative design. |

Low Impact Material Handling |

All in One Compact SolutionRadyne offers full turnkey cartridge annealing systems that are ready to run and produce the profile you need when it arrives on your shop floor. |

Commercial, Military, Competition Grades |

Precise. Rapid. Repeatable.Radyne’s Induction Process Engineering Center offers a full turnkey metallurgical analysis of your cartridges and their cold-worked state as well as the development of the right heating profile to deliver the results you need for the highest quality product. |

Repeatable Results |

Lead Bonding:

Radyne offers induction heating equipment for bullet lead bonding with its unique patented super high-efficiency heating you can save tens of thousands per year in energy costs while delivering the highest quality bonds in the industry.

Tech Specs

| Annealing System 110 | Annealing System 320 | |

| Speed: | Up to 110 cartridges per minute | Up to 240+ cartridges per minute |

| Part Size: | 4.6 mm-7.6 mm | 4.6 mm-7.6 mm |

| Dimensions: | 60W x 72D x 108H in[152W x 182D x 274H cm] | 223W x 141D x 142H in[566W x 358D x 360H cm] |